If you were to list the ten most important sites for the emergence of Detroit as an industrial metropolis, this would be among them. You do not often assume that the Crimean War played a role in Detroit’s rise, but in a very indirect way, it did. The Iron Age began about 1200 when people in the Mideast discovered how to make tools out of iron. The ideal tools were not exclusively iron, but used iron mixed with other metals. One of the developments was the manufacture of steel. Iron ore may be heated to a great temperature and will lose some of its impurities. The resulting iron, however, will be strong but brittle and difficult to shape or use for tools that men and women might carry. At some early date, metal workers discovered if they heated iron at a very high temperature for a very long period of time, they would produce a product we know as steel. The heating of iron removes more impurities and yields steel that has many desirable properties. Steel is very strong and durable, may be shaped quite easily and other minerals or chemical may be mixed with it to give it specific properties.

Steel or metal products derived from iron date to the early Iron Age but they were uncommon. A major reason was the tremendous amount of work that was required to heat iron so that it would lose its impurities and become steel. When guns became common for warfare, much steel was needed. But there were major challenges in finding iron ore that could be heated to derive iron and then there was the problem of heating the iron for a week or more at extremely high temperatures to produce steel. You needed a tremendous amount of charcoal to heat the iron. By the Nineteenth Century, a blooming process had been developed in which iron was place in stone lined vats and heated, perhaps for a week or more, to produce molten steel. The entire process was extremely costly to accomplish.

Henry Bessemer, an Englishman, was not a metallurgist or engineer but he was interested in supplying the British Army with steel for the guns and arms it needed for the Crimean War. I believe that he designed and produced artillery using steel. This was one of the first of the modern wars that used manufactured goods extensively. The American Civil War was an even more “modern” war that capitalized upon technological developments in the manufacture of iron and steel. Bessemer claimed that he accidently found out that if you exposed molten iron to air, its temperature would increase. The increase in temperature burned off impurities and produced steel. Apparently, he got the idea of injecting air—either hot or cold—into molten iron. You might think that blowing air would reduce the temperature of the iron such as blowing air on hot soup cools it. That is not the case. The air increases the temperature of the iron and rapidly produces steel by burning off some impurities while others form a solid slag that may easily be removed from the liquid steel.

Bessemer patented his idea in 1855 and quickly set about designing and producing the equipment needed for what has become known as the Bessemer process for making steel. The first installation in England of a Bessemer converter was in 1857. A key was the large vat he designed called a Bessemer converter. Bessemer, of course, was not the only person attempting to design and effective and cheap way to produce steel from iron. Similar to many other Nineteenth Century inventors such as Alexander Graham Bell, he spent very much of his later life fighting off challenges to his patent.

William Kelly, born in Pittsburgh in 1811, studied metallurgy at the college that later became the University of Pittsburgh. By 1846, he had purchased an iron factory in Eddyville,, Kentucky. His factory began with iron ore, heated and treated in a complicated manner and produced what were known as iron blooms, large blocks of more or less pure iron. These would then be converted to steel in the laborious process mentioned above. As early as 1847, Kelly began experimenting with what he called an air-boiling process in which he forced air into molten iron. By 1851, he apparently was beginning to produce steel in this cost saving manner.

Apparently, there is some evidence that those working with Bessemer in England had learned about what Kelly was doing in Kentucky and tried to imitate the process. Many people were attempting to improve the production of steel since the demand for industrial products was growing rapidly. Kelly, however, did not obtain a United States patent for his process until 1857. Unfortunately, he went into bankruptcy in that year and had to sell the rights to his patent for a small sum. Steel making firms wishing to use the Bessemer paid for the use of the patent but 95 percent of the funds went to Henry Bessemer and only 5 percent to William Kelly. It is no wonder that the Bessemer process came to dominate steel making since it produced steel for about 15 percent of the cost of the previous blooming method.

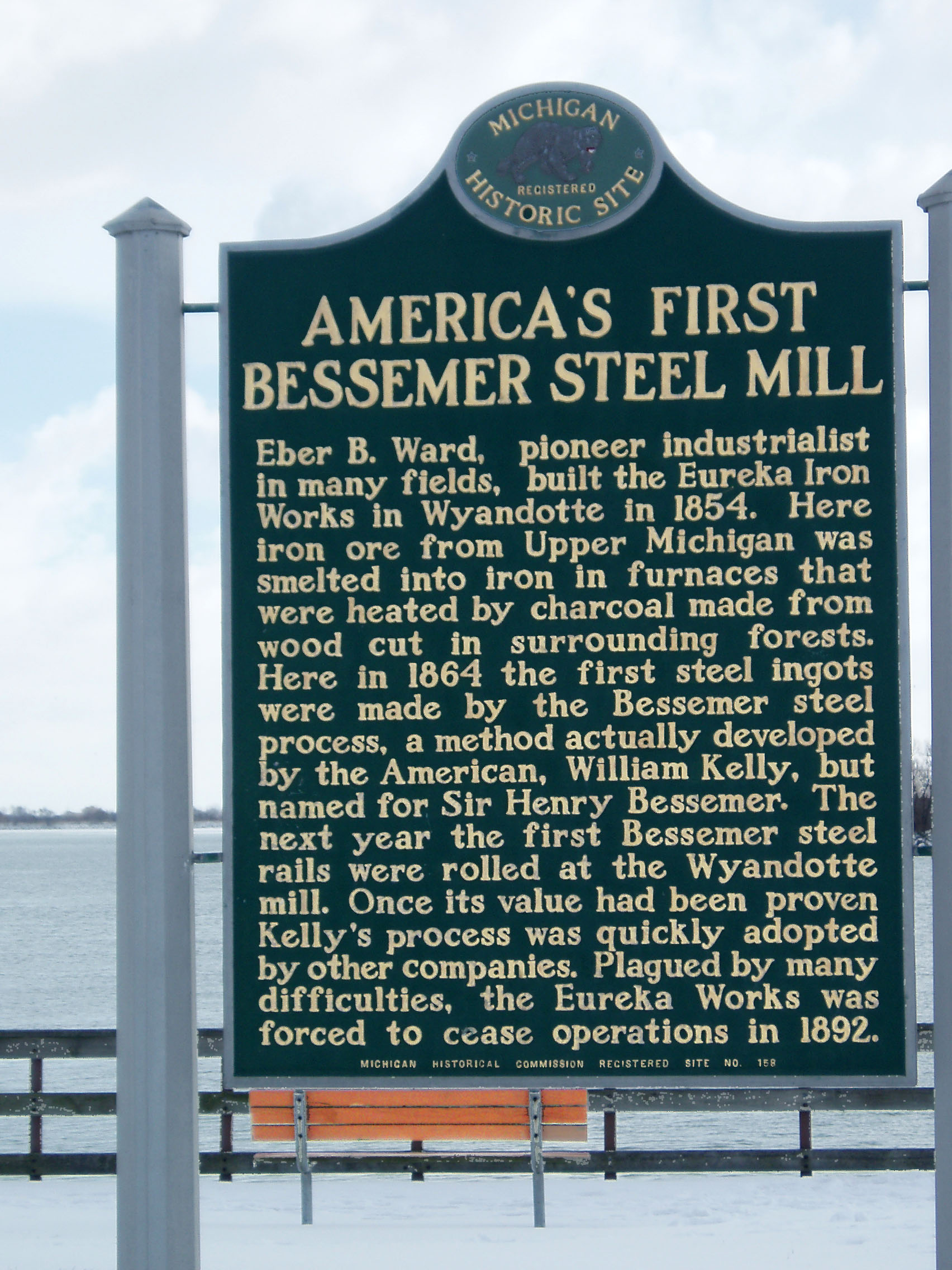

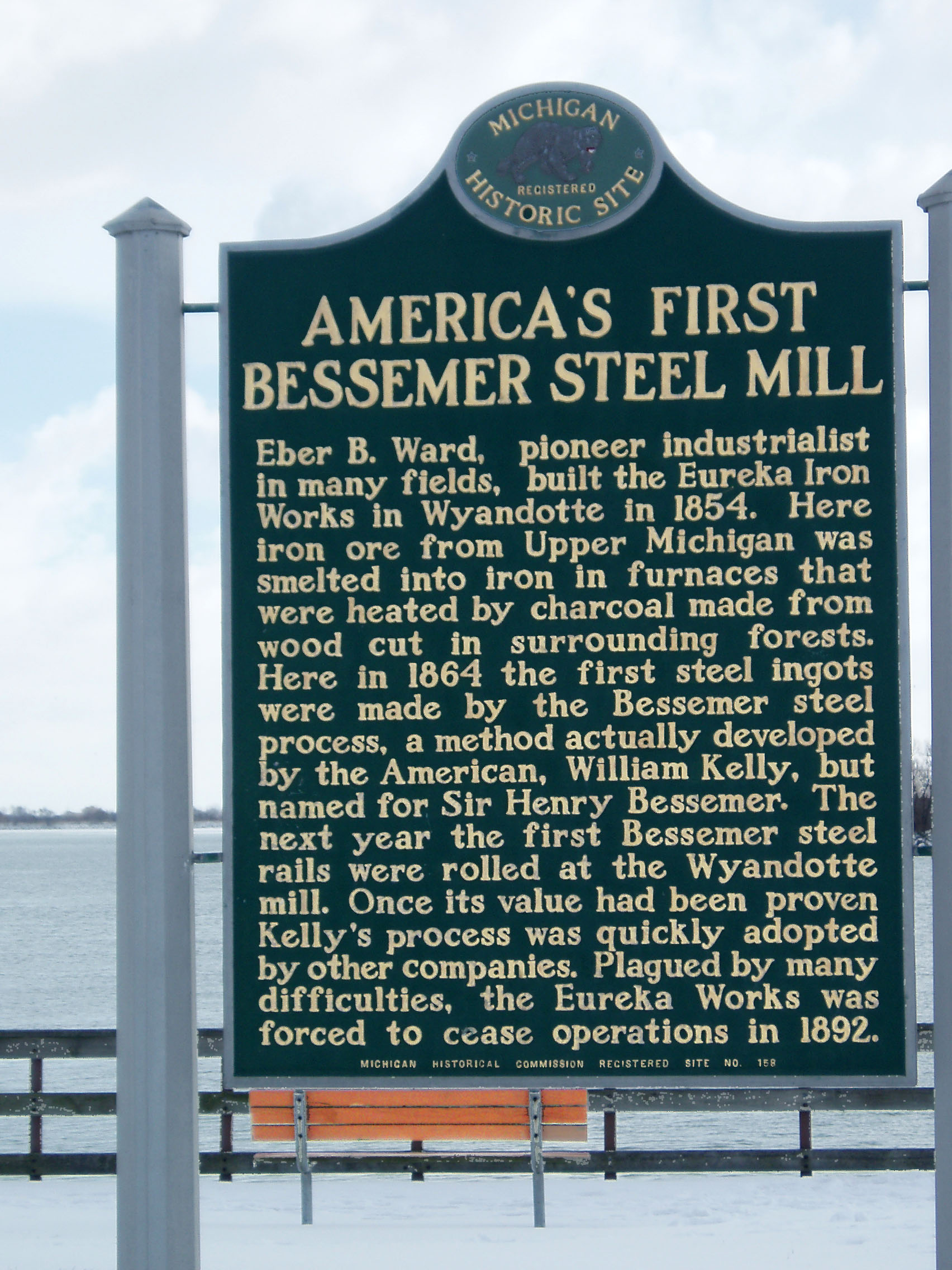

Eber Brook Ward was the founder of the Eureka Iron Works here in Wyandotte. He was Michigan’s first multi-millionaire. He made his fortune buying timber lands in the Lower Peninsula, in silver mines in the Upper Peninsula and by owning a Great Lakes shipping line. In the early 1850s, he decided to operate an iron mill and ship building yard here in Wyandotte. Apparently, he wished to modernize his business so, in 1864, his firm was the first in the United States to use the efficient Bessemer method to produce steel. Mr. Ward died in 1875. The tremendous economic crisis of 1892 wiped out many firms and impoverished numerous people. Eureka Iron Works went under in that economic depression.

The Bessemer process dominated the steel industry into the Twentieth Century when the Open-Hearth method became much more cost efficient. The Open Heath method, in turn, was supplanted in the 1960s by a new process that had been invested in Austria. This basic oxygen process used a water cooled lance that injected very pure oxygen into a vat of molten iron along with various chemicals to produce low nitrogen steel about three times as rapidly as in the open hearth method. There is a National Historic Mechanical Engineering Landmark marker at the site of the former McClouth Steel plant commemorating this innovation in steel making. Alas, the McClouth Steel Company, similar to the Eureka Iron Works, went out of business.

State of Michigan Registry of Historic Sites: P25366; Listed September 17, 1957

State of Michigan Historic Marker: Placed here April 4, 1958

Photograph: Ren Farley; February 12, 2006

Description prepared: February, 2012